In the field of industrial automation, accurate detection is the core link to improve production efficiency and product quality. In the face of complex and changing production line environment, traditional photoelectric sensors often fail due to background interference, color differences or harsh environment. With years of technical accumulation, FWE has launched the FJN10 series of square-type background suppression laser sensors, which redefine the industrial detection standard with revolutionary design and inject high-reliability solutions for intelligent manufacturing.

A breakthrough in core technology: background suppression function empowers accurate detection.

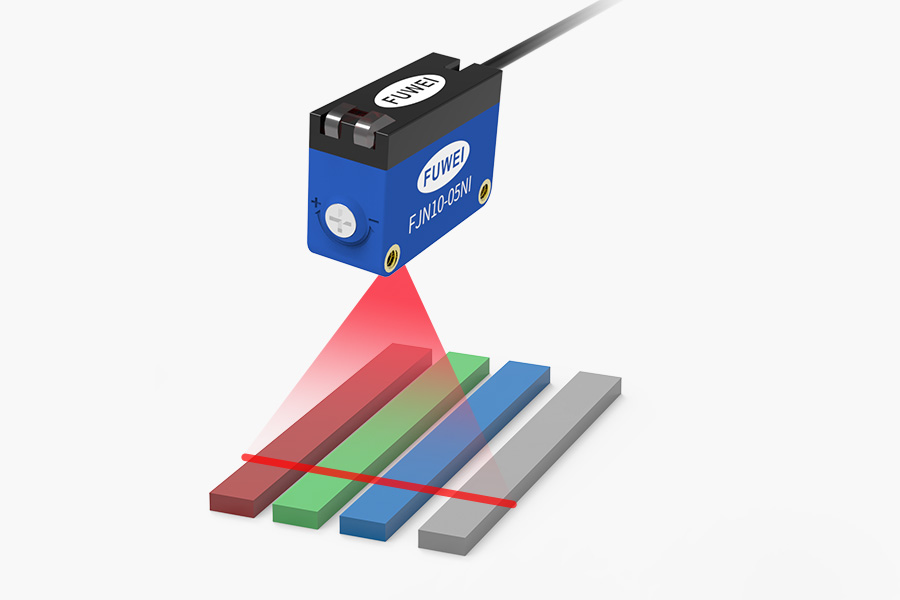

The core advantage of FJN10 series laser sensor lies in its BGS (background suppression) function. Through intelligent algorithms and optical systems work together, the sensor can accurately distinguish between the target object and the background reflection, even if the detection object and the background color is highly close to each other, it can still be a stable output signal. This feature completely solves the problem of misjudgment of traditional sensors in the dark color/light color material switching scenarios, especially for food packaging, automotive parts and other industries that need to deal with multi-color products.

Compared with ordinary photoelectric sensors, the laser sensor through the red laser projection element to generate a high-density spot diameter of less than 1mm, with 635nm visible red light design, so that debugging personnel can intuitively locate the detection area, significantly shorten the time for equipment installation and calibration. Spot concentration increased by more than 30%, even in the face of tiny parts or hollow structures (such as mesh tray, gear tooth gap), but also to achieve millimeter-level accuracy and stability of detection.

Second, hard-core protection + environmental adaptability: fearless of harsh challenges

Industrial sites are often accompanied by dust, oil, water mist and other disturbing factors, FJN10 series of laser sensors to IP65 protection level to build a solid line of defense. Shell using high-strength engineering plastics and sealing structure design, can resist high-pressure water jet wash and dust intrusion, in food processing, mining machinery, outdoor equipment and other scenarios of excellent performance. Experimental data show that the sensor in the -25 ℃ to 55 ℃ wide temperature range still maintains ± 0.1mm repeatability detection accuracy, to ensure that the cold chain storage, high temperature casting and other special working conditions of all-weather stable operation.

Multi-scenario application: unlocking the new possibilities of intelligent manufacturing

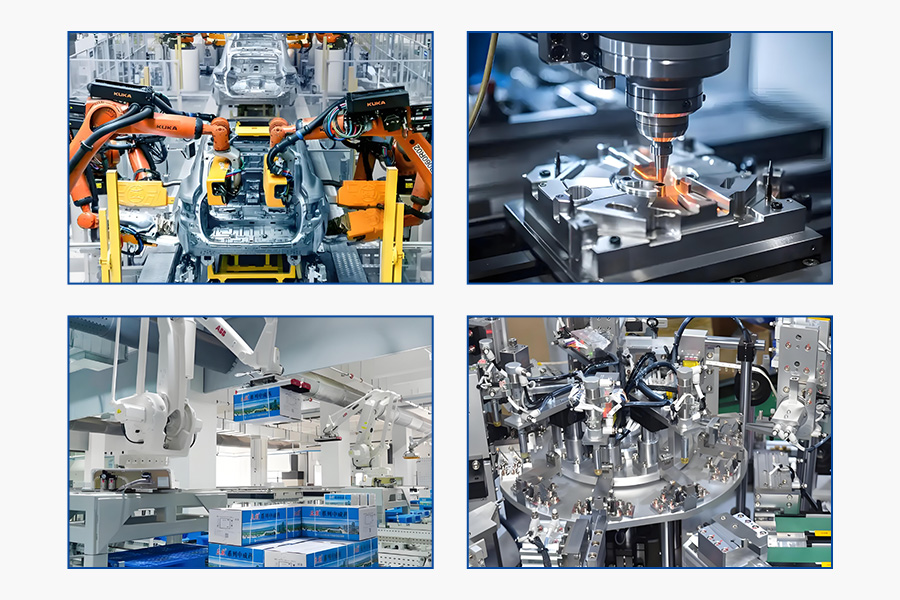

Multi-color material sorting system

In the 3C electronics and cosmetics packaging line, the sensor ignores the color difference between the outer packaging of the product, accurately identifies and locates the product, and completes high-speed sorting with the robotic arm, increasing the yield rate to 99.8%.

High-precision assembly inspection

For precision bearings, chip pins and other micron-sized parts, the laser sensor filters out reflective interference from the equipment through the background suppression function, realizing sub-millimeter size measurement, and helping the semiconductor and medical device industries break through the quality control bottleneck.

Complex Surface Inspection

For uneven casting surfaces or hollow metal mesh plates, the sensor can penetrate the surface texture differences by adjusting the detection threshold, accurately identifying defects such as missing parts and deformations, and successfully replacing the manual visual inspection in the inspection of new energy battery modules.

In the wave of Industry 4.0, the FJN10 series of laser sensors, with its anti-interference, high-precision and strong durability, is becoming a core sensing element for the upgrading of smart factories. Whether it is to improve the efficiency of the existing production line, or to lay out the future of flexible manufacturing, this laser sensor, which redefines the industry standard, will bring significant cost reduction and efficiency gains for enterprises.